Chain Guide

Files

Edit this page | Download FilesSource |

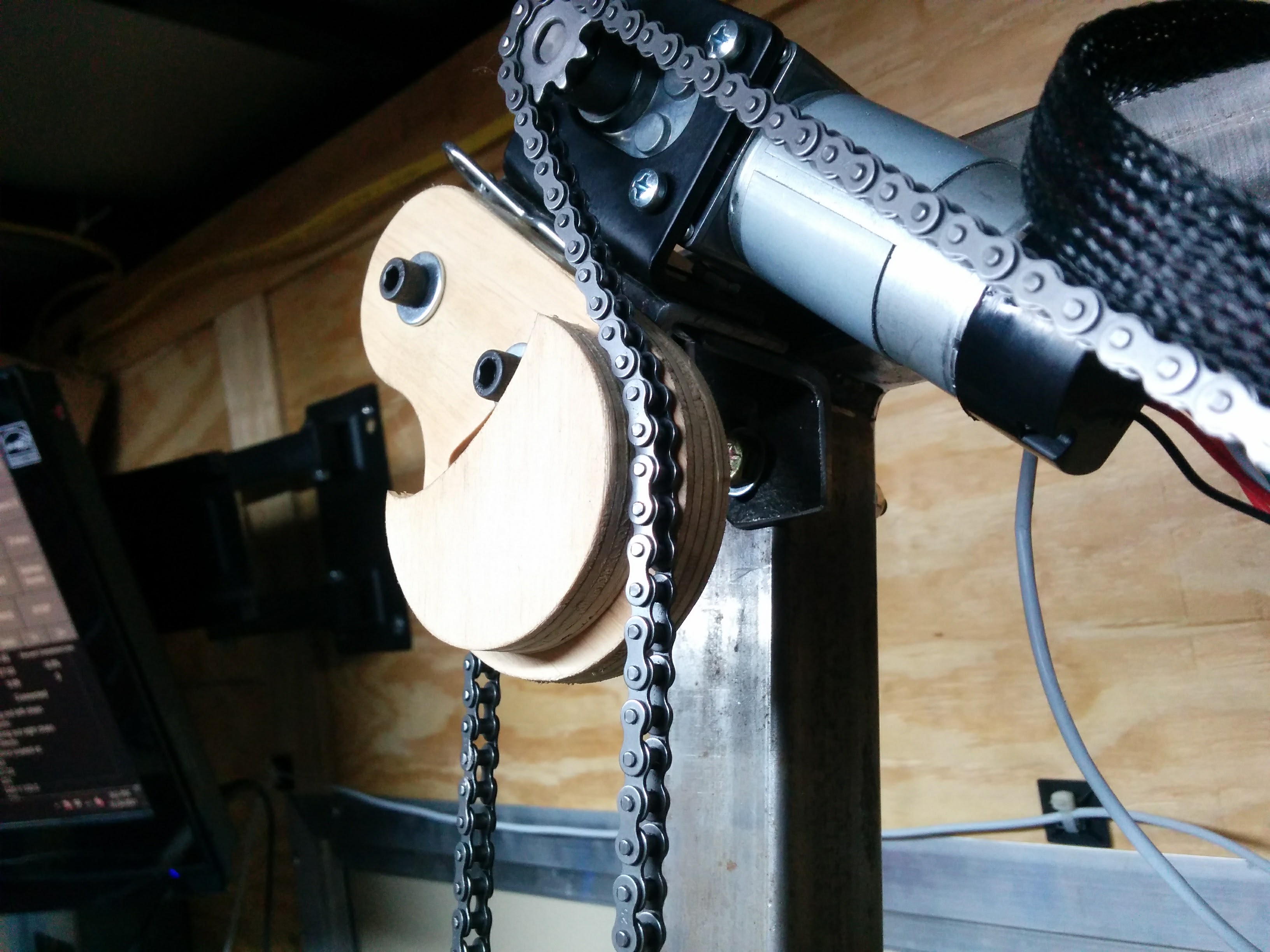

Chain Guide

A chain guide to increase chain engagement with the sprocket on the original frame

The guide is made from two layers of 12mm (~1/2") plywood. I designed the pattern to be reversible, that way I could make one program for both the right and the left motors. I ran two screws through the back of the bigger part to secure the smaller part. You could also glue and staple it if that works for you. The most important part of the assembly is the smaller piece is roughly centered on the larger piece.

The NC file is programmed to use the 1/4" 1 flute bit available from the Maslow store. The feeds and speeds can be changed either in the NC program using find/replace for other 1/4" bits, or by opening the nest file and changing the tool used for the operations for other sized bits.

Provided are - An assembly model in Fusion360 native format - An assembly model in STEP format for other CAD platforms - A nest model in Fusion360 format, to tweak CAM settings - The proven NC file I used to make the part

Here is the guide from another angle:

Instructions

Edit this pageAs far as mounting to the frame, I made up a mounting bracket from 1 1/2" x 1/8" steel angle. I drilled two holes in one leg that match up with the motor mount. This way my bracket sandwiches between the motor bracket and the mounting bracket I made for the frame. In the other leg, I drilled and tapped two 1/4"-20 holes 42mm (~1 5/8") on center for the guide screws.

That being said, it would be quite easy to simply attach the guides to the wooden stock frame. There may need to be a riser or something in the system to make sure it aligns with the chain sprocket. As much as I really like my steel frame, it requires me to do a little more thinking as to how to attach modifications.